Radiation Therapy: External Beams

By Dr. Zoomie

This article is part two of a two-part series on radiation therapy. Read about Brachytherapy: ...

Read morequestions? Call us

By Dr. Zoomie

This article is part two of a two-part series on radiation therapy. Read about Brachytherapy: ...

Read more

By Dr. Zoomie

This article is part one of a two-part series on radiation therapy. Read about external ...

Read more

By Dr. Zoomie

Dr. Zoomie! Going through the cabinets of a few recently retired engineers at work I ...

Read more

By Dr. Zoomie

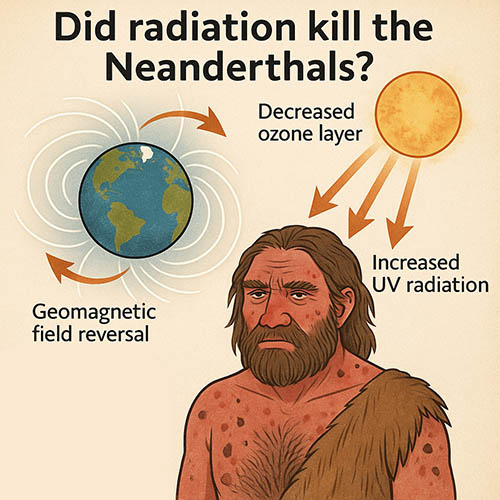

Did radiation kill the Neanderthals? So, Dr. Z – I saw something in my feed ...

Read more

By Dr. Zoomie

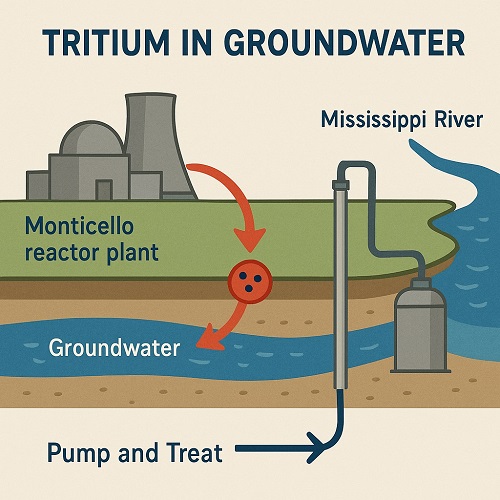

Tritium in the groundwater? Hey Dr. Z – I live in Minnesota, near the Monticello ...

Read more

By Dr. Zoomie

Interstellar Fission? I’m puzzled, Dr. Z. I read what you wrote about the natural nuclear ...

Read more

By Dr. Zoomie

Hi, Dr. Z – I was reading through some of our regs the other day ...

Read more

By Dr. Zoomie

Dear Dr. Zoomie – I liked the piece you wrote about how particle accelerators work; ...

Read more

By Dr. Zoomie

Good evening, Dr. Zoomie! I was reading something about being able to study isotopes to ...

Read more

By Dr. Zoomie

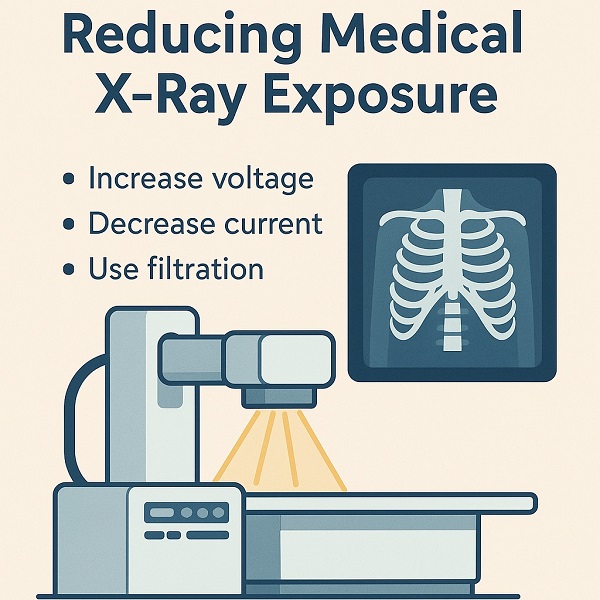

Yo, Doc Z! I was wondering if you can tell how they make x-rays and ...

Read more