Say, Dr. Zoomie – Seems I’m starting to hear about small modular reactors lately. To me, it just sounds like a bunch of small reactors. I thought bigger reactors were supposed to be better – what’s the big deal about a bunch of small ones?

Yeah – I can see how it can come across that way. When we scale up from, say, 100 MW to 1000 MW of output we do benefit from economies of scale – it’s cheaper (in theory, anyways) to build a single 1000 MW reactor than to build 10 smaller plants. But there’s more to the matter than just economies of scale – that’s what I want to start with; after that I’ll also discuss two specific types of modular reactor.

Let’s start with why we’re suddenly hearing more about these lately – global climate change. Nuclear energy produces a lot of electricity without releasing very much CO2 – it’s one of the few forms of energy production that can be placed pretty much anywhere and that can produce energy round the clock and regardless of weather. In comparison, geothermal energy is only useful in areas with a high geothermal gradient, wind power is only possible in areas with strong and steady winds, solar power only works when the Sun is shining, it’s hard to capture the energy of the tides in (say) Wyoming, and so forth.

There are two approaches to building a fleet of large nuclear reactors. One approach is to use the same design for every single reactor, tweaking the design only as needed to fit the exact location where it will be built – not the reactor or steam system but, rather, the source of cooling water (e.g. lake, river, ocean), the degree of seismic protection, seawalls to protect against large waves, and the like. This approach is used by most of the world’s nuclear nations. One major advantage to this approach is that there’s only the need to do one full-plant design review and certification, saving years of time during the licensing process as well as simplifying writing operating procedures, developing training programs…not only that, but it’s easy for operators and technicians to move from reactor to reactor if they all have the same design.

I can vouch for this personally – the Navy’s nuclear power program uses standardized reactor designs; the land-based reactor on which I trained and at which I was an instructor was nearly identical to the reactor plant on the submarine I transferred to. The day I arrived on the submarine I took a tour of the engineering spaces and realized that I could step right in and do virtually any operation I’d been able to perform at the training reactor – the only ones I had to stop and think about a tad were those using one of a handful of valves that were placed just a little differently than at the training reactor. I’ve talked with Canadian and French reactor staff – they told me that their plants are pretty much the same. It saved me months of training time – as it does for other nations using this approach.

The other approach is to design a bespoke reactor plant for each location and customer so that each reactor is unique. The advantage of this approach is that each reactor plant is optimized for the customer and for the terrain and other conditions of the exact site on which it will sit. The disadvantage of this approach is…well…pretty much everything else. Because every reactor is different, every single plant requires full regulatory review and approval, it’s hard to develop standardized procedures, every operator has to be trained on every plant at which they work, and so forth. It is the most expensive approach to take when it comes to designing, building, and operating a nuclear reactor fleet. This is where modular reactors come in.

The idea behind modular reactors is that every reactor plant will be identical – in a sense, the reactors I learned to operate in the Navy were modular reactors. Not only that, but modular reactors can be easily added to as the demand for energy grows – not exactly plug-and-play, but it’s easier to drop a new module into an existing location than to plane, design, license, and build a new reactor facility at a new location. There are two main modular reactor designs at this time – the small modular reactor (SMR) and the pebble-bed modular reactor (PBMR – a modular design).

Small Modular Reactor (SMR)

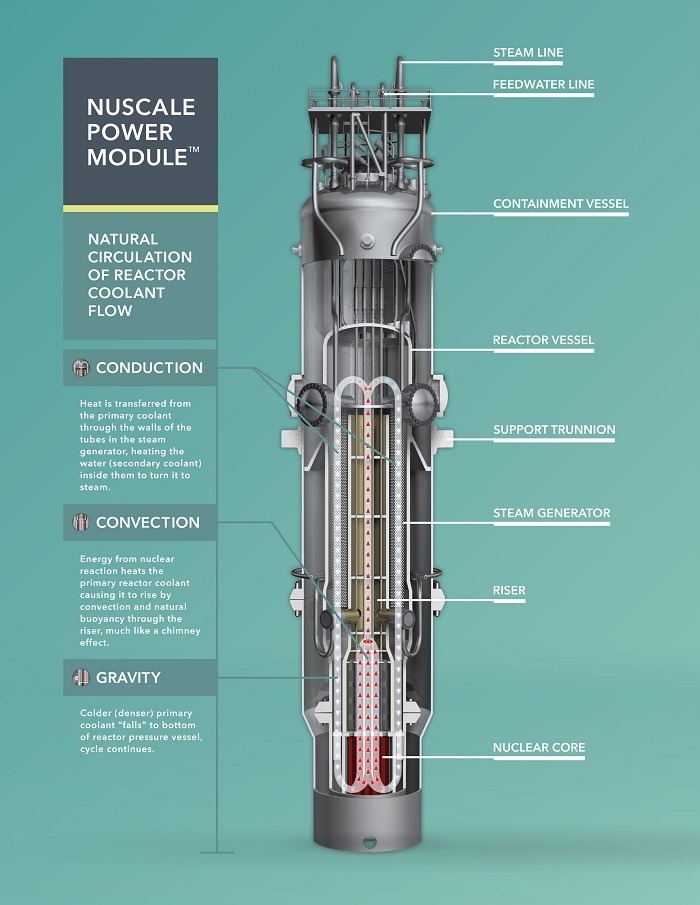

Small modular reactors are designed to be built in a factory and shipped to the site for installation. With a design power output anywhere between 5 – 300 MW the SMRs can power a neighborhood, a factory, a desalinization plant, or a small city, adding additional modules as population and energy needs increase. This approach loses the economies of scale of a single 1000 MW-class reactor, but it gains economy of scale in another sense by making it possible for a single factory to crank out nuclear reactors on an assembly line.

On top of this, the SMR designs currently in use, approved, or under review are new designs that take advantage of 80 years’ worth of operational experience, improved materials, engineering advances, and safety systems. For example, advances in materials science make it possible to operate at higher temperatures and pressures that offer greater thermal efficiencies; design advances make it possible to add passive safety systems that reduce the already-small risk of accidents. On top of that, a simpler plant design should require less maintenance and fewer operational and maintenance staff.

Source: https://commons.wikimedia.org/wiki/File:Diagram_of_a_NuScale_reactor.jpg

As of this writing there are as many as 80 different designs for SMRs in various stages of development in 19 nations – these numbers are sure to change as designs are dropped from consideration and as new ideas crop up. Most of these designs are for pressurized water reactors, but gas-cooled, molten salt, heavy-water, boiling water, and lead-cooled fast neutron designs (compared to the more typical slow – or thermal – neutron design) are also in various stages of planning. But with all the designs on the drawing boards in so many nations, at present only China and Russia are actually operating any (Russia’s is a floating reactor plant while China’s is a variant SMR called a pebble-bed reactor – discussed below).

In the US things are…interesting. Some heavy hitters in the nuclear power industry – Westinghouse, General Electric, and General Atomics are among the companies designing these smaller reactor plants (alongside a number of companies I’d never heard of before researching this answer). Some designs are in review by the Nuclear Regulatory Commission and one design was actually approved for construction until economics caused that project to a halt when investors pulled out. But the process does seem to be lurching forward and, we can hope, there might be some SMR reactors that come online in the US in the next decade or so.

Pebble-bed modular reactors (PBMR)

One type of SMR is the PBMR – an idea that’s actually been around since 1947 (as has the name). The idea is to combine the fuel and moderator into a small sphere that’s strong enough to also provide some structural support and that will contain the waste fission products – the “pebble.” By surrounding the fuel with graphite, neutrons are slowed down as they pass through the shell, reducing the need for water as a moderator. This makes it possible to use a gas – helium or air for example – to cool the fuel pebbles and to transfer that heat; if helium is that gas then it can be used to spin power turbines directly as helium doesn’t become very radioactive when exposed to neutron radiation. In addition, graphite’s excellent high-temperature performance means that these reactors can gain thermal efficiency by heating the helium to higher temperatures than in most water-cooled reactors.

What’s cool about PBMRs is that refueling is simple – fresh pebbles are loaded at the top and spent pebbles are removed from the bottom; it makes me think of a gumball machine. The mechanism is relatively simple, the pebble’s design contains the radioactive waste as well as reducing radiation exposure to the operators and maintenance crews, but the design makes it more difficult to recycle the fuel if that’s a goal.

The world’s first PBMR was built in Germany in 1966 and operated for 21 years before being shut down. China and South Africa have also licensed and constructed PBMRs, although they don’t have much operational experience with this design as of this writing. As that operational experience grows, it’s likely that the design and operating procedures will be tweaked from time to time to take advantage of the lessons that are learned during an increasing number of reactor-years of experience. In addition to South Africa, China, Russia, the US, and other nations, a few companies are looking at this design to power reactor for power generation in spacecraft.

There are other modular reactor designs – too many to go into here. But most of these designs are scaled-down versions of larger reactor designs I hope to discuss in future posts.

References:

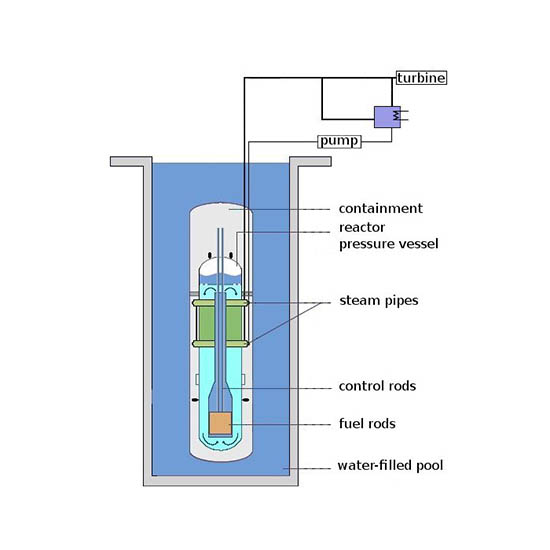

- Header image source: https://commons.wikimedia.org/wiki/File:Pumpless_light_water_reactor.jpg, created by KVDP